EMC cable glands - Electromagnetic compatibility

Why are EMC glands needed?

EMC is the short form of ElectroMagnetic Compatibility, EMI means ElectroMagnetic Interference. According to EU guidelines EMC is defined as “to limit the electromagnetic emissions for equipment in order to ensure that, when use as intended, such equipment does not disturb radio and telecommunication, as well as other equipment and additionally such equipment is immune to interferences and is not disturbed by radio emissions”. EMC cable glands protect against electromagnetic interference fields and thus make a decisive contribution to the fault-free functioning of machines and systems. In times of steadily increasing automation and digitalisation, this is an indispensable aspect.

Such electromagnetic (EM) disturbances can occur whenever systems are driven by alternating current and/or controlled by frequency modulated signals. Such systems nowadays are used for high efficient production lines. The disadvantage coming alongside is electromagnetic smog which has to be avoided by suitable and cost-effective means.

The only reasonable remedy against EM smog will be a totally EM-shielded system! This shielding will start at the electronic board, will be continued by a conductive housing/box and screened cables. As these cables could act as active or passive antenna their outer sheath must also be an integral part of the earthing system. Normally this is done by a cable gland or a connector. In both cases the electrical connection should show low impedance. This is to ensure high damping up to high frequencies in the GHz-regime.

For this reason EMC cable glands will be used: they realize electromagnetic connection between cable sheath and electrical ground of the housing. Such a closed Faraday cage will fulfill the above mentioned EU guideline – there will be no electromagnetic smog!

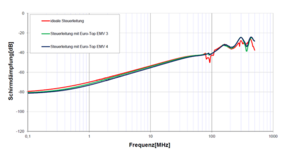

Our patented EMC system inside the gland guarantees a low impedance contact. It is designed to perform excellent even under harsh environmental conditions without fading during the complete lifetime of the system. Simultaneously our EMC glands can easily be installed without disassembling it.

Production lines are getting more and more challenging to improve production efficiency. Therefore powerful frequency modulated technics are used. In a lot of cases these technics induce parasitic, high amperage alternating EM currents into the cable screens. Among others such technics are PWM (Pulse Width Modulation) and VFD (Variable Frequency Drive). Electrical currents up to several hundreds of Amps could occur this way and must therefore securely be grounded. For such high currents normal EMC glands will fail. For such applications we developed our Euro-Top EMC Ampacity cable gland which adds another feature to the above mentioned: Carries high current load.

This was realized by increasing the contacting cross-section between cable sheath and cable gland. Although this was a tremendous additional challenge it doesn’t neither impact the excellent shielding characteristics nor the easy handling.

Both when using an EMC cable gland and when using a connector, we assume that a braided control cable for electromagnetic shielding is used - and in both cases the cable shield will be grounded inside the gland/connector by means having a low impedance. This way the cable braid will be disrupted.

But how about the single cores inside the cable? These are the main elements which carry information and energy. Therefore these signals should arrive at their destination without any disturbance or attenuation.

Figure 1 shows both applications: whereas the single cores are fed through the gland reaching their goal directly they are separated inside the connector. In this last case a number of serial resistances R2 to R7 are created inside the connector – additionally to R1 which is the original resistance of the single core itself. This generates a total resistance of RƩ.

Although these resistances will be small they will sum up to an additional loss of electrical power inside the connector which can be calculated as P=I2*RƩ. This has to be considered especially in the case of high amperage and weak signals.

Therefore cable glands will be preferred in such cases – which are among others PWD and VFD technics, direct current photovoltaic or e-mobility applications. Our Euro-Top EMC glands will always be the right choice to guarantee uninterrupted feedthrough of energy and signals.

RST offers a wide-ranging portfolio of application-specific solutions: