Basic information

Condensation forms in enclosures due to temperature and pressure fluctuations caused by the environment, climate and the actual operation of the system. Excess air humidity condenses at the coldest points in the enclosure. Venting nozzles and drainage nozzles reliably prevent the formation or accumulation of condensation water. Maintenance and repair costs for electronic and electrotechnical components are significantly reduced in this way. In addition to an extensive range of plastic and stainless steel venting spigots, combined with important approvals - including those relating to UV resistance or the possibility of use in potentially explosive atmospheres - RST offers a wide-ranging portfolio of application-specific solutions.

From...

- Mini versions in M8x1.0 or M6x0.75, which are playing an increasingly important role in times of ever smaller electronic and electrotechnical components,

- to cable glands with integrated pressure compensation function, which combine the properties of conventional cable glands with those of a pressure compensation element in one product,

- up to our new safety vent connectors, which primarily provide for pressure equalization, but also function as a pressure relief valve in case of emergency (mainly used in the field of Li-ion battery technology),

...we have the right solution for almost any challenge. And should the formation of condensation water actually be unavoidable, a wide variety of drainage nozzle designs provide a remedy.

What you need to know about venting spigots

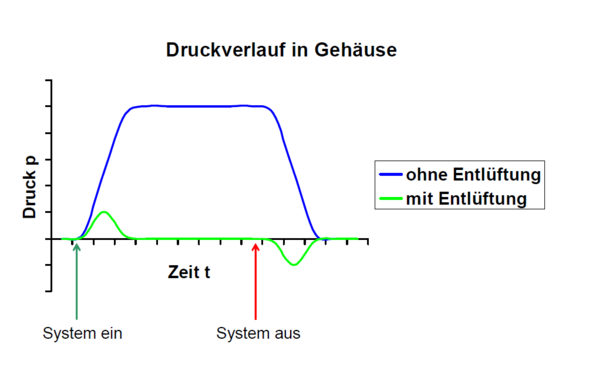

A vent ensures that the pressure difference between the inside of the housing and the surrounding atmosphere is equalized. The differential pressure inside/outside is thus ΔP= 0.

To begin with, a vent does not fulfill the following functions:

1)Permanent air circulation into the housing2) Cooling3) Dehumidification of the enclosed air.

The maximum temperature in an enclosure depends on:

a) The ambient conditionsb) The power dissipation of the (electronic) components in the enclosure.c) The housing designd) The type of cooling/cold bridges

A vent therefore "only" balances the ambient conditions outside with the internal atmosphere inside the enclosure, taking into account the parameters "ambient atmosphere", "energy dissipation inside the enclosure" and its "design features". A vent does not serve to reduce the temperature inside the enclosure; this can only be realized by appropriate, active components.

The balancing of internal and external pressure prevents seals, feedthroughs and operating elements on the housing from being stressed by overpressure that would otherwise occur, thus reducing their service life. Furthermore, a high degree of protection of IP 67 and IP 69 is achieved despite air exchange. Last but not least, the continuous pressure equalization via a diaphragm prevents condensation and corrosion inside the housing.

The functionality of a vent

Two parameters determine the functionality of a vent:

- the permeability (Air Flow Rate, AFR)

- the Water Intrusion Pressure (WIP).

Both parameters are interdependent for a given membrane type and are further influenced by the design of the vent. A vent should have a high permeability and also ensure the highest possible water inlet pressure. Normally, the permeability of a vent nozzle is specified at ΔP=70mbar (hPa). Thus, different vent nozzles can be compared with each other. 70 mbar corresponds to the US unit 1 PSI (= pounds per square inch), 1 hPa corresponds to 100 N/m2, 70 mbar thus 7,000 N/m2.

With the same membrane type and the same active area, an increase in permeability means a reduction in the water inlet pressure (WIP), which in turn affects the IP protection class. This effect should be taken into account during planning: the maximum ΔP should not exceed the WIP, especially not in the cooling process, as otherwise water can be sucked into the housing with the outside air.

The diaphragms used in air vents allow air to pass through both sides, but block water, other liquids and dirt/dust. This allows a high degree of protection such as IP 64, IP 65, IP 67 and IP 69 to be achieved even though the system can breathe. When using a vent, do not aim for IP 68 protection, as a system cannot "breathe" under water (except with a snorkel).

The water present in our atmosphere in the form of gaseous water vapor, can diffuse through the membrane - in both directions, since the membrane is bi-directional! If condensation has already formed in the housing during operation or as a result of the production process, this is gradually pumped out by further operation. Several on/off cycles are necessary for this. In the equilibrium state finally reached, the humidity in the housing is identical to the humidity in the surrounding atmosphere. This process depends on the temperature difference inside/outside: the higher this difference, the faster equilibrium is reached. Assuming that the temperature inside the enclosure is always slightly higher than outside, condensation will not occur.

These considerations are important when designing a system. A pressure equalization element should always be placed at the top of the side of the enclosure. This will largely prevent blockage of the diaphragm by water or dirt. Our vent glands can be used in the same manner as normal cable glands, i.e., wherever cable entry into an enclosure is necessary.

The vent gland calculator https://www.druckausgleichsrechner.de/de/ on our website is an excellent tool for determining the appropriate vent gland for the corresponding application.

The use of a drainage socket

As described above, a drain plug can usually prevent the occurrence of condensation in an industrial enclosure. However, in some applications, the use of a drain socket is essential. This depends on the environmental conditions, the application and the installation.

Water vapor usually condenses at so-called cold traps - the coldest points in the system. At these points, the dew point is exceeded, i.e. the vapor phase changes to the liquid phase. Let us look at a practical example: at an air temperature of 30°C, the saturation density of water is 30 g/m3 (=30 mg/ltr, i.e. one liter of air contains 30 mg of water); at a relative humidity of 70%, this is 21 mg/ltr. 21 mg/ltr corresponds to the saturation density at 19°C, i.e. from T<19°C, the water vapor precipitates - condensation water is formed. At a relative humidity of 40% (@30°C) the water content is 12 mg/ltr and the dew point is 11°C.

30°C @ 70% rel. humidity: condensation occurs when cooled down to 19°C; ΔT=11°C.

30°C @ 40% rel. humidity: condensation occurs when cooling down to 11°C; ΔT=19°C.

From this example, it can be seen that at high relative humidity, the temperature difference before condensation forms is less than at low relative humidity. In other words, at high relative humidity and rapid temperature changes, a drainage spigot is the right choice.

Drainage sockets are placed at the lowest point of the enclosure to allow the condensation water to drain off by means of gravity.

Summarized for you:

In most applications, venting spigots or fittings) prevent the formation of condensation in housings. In some critical applications, a drain socket is necessary. Sometimes we are asked if a combination of vent stub and drain stub can be used. Since the majority of our drain sockets are IPx5 rated, this is an alternative for one application or another.

Nevertheless, there are special applications where neither venting spigots nor drainage spigots can prevent condensation. Both products are passive components whose functionality depends only on the ambient and application conditions. These can only be influenced by active air conditioning: a vent or drain socket will not help here. We will be happy to help you with customized solutions!

For more information about venting nozzles, drainage nozzles or other, please contact our specialists at